Product Finishing

Our breadth of industrial experience means that our talented team has extensive experience with many types of product pre-treatments and finishes; essential for increasing product life and adding value.

We offer a reliable, single point of contact for finishing your products, using a combination of in-house processes and specialist finishes delivered by trusted external partners. These processes include:

- Degreasing

- Shot blasting

- Nylon powder coating

- Galvanizing

- EP and powder coating

- Stainless steel polishing.

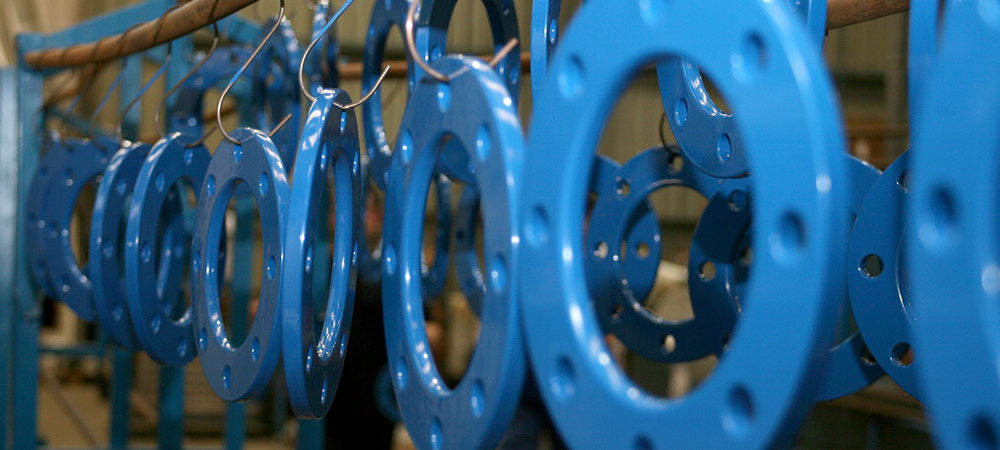

Nylon and Antimicrobial Coatings

ASG is a recognised market leader in the expert application of advanced nylon powder coatings.

When compared with industry-standard epoxy polyester finishes, nylon powder coatings offer increased resistance to impact, abrasion, corrosion and chemicals, as well as being more hygienic and ecologically sound.

As we work with a wide range of applications, across a breadth of industries, we have adopted the highly versatile and cost-effective fluidised bed dipping process. This allows the nylon coating to be applied on all types of metals, with a controlled thickness of between 250-500 microns. Coating up to 2mm is also achievable, with minimal tooling costs.

Other advantages of nylon powder coating:

- Reduced thermal conductivity

- Low friction coefficient

- Mechanical strength

- Durability

- Wide colour range.

We are one of only a handful of companies entrusted to apply the exclusive Rilsan Active anti-microbial coating, which help control the risk of bacterial contamination, especially in areas where high standards of hygiene and cleanliness are both a requirement and a responsibility.