Advanced Laser Cutting

In recent years we have a made a considerable investment in advanced laser tube cutting technology, which has now placed us at the forefront of UK manufacturing in this area. It’s an investment which not only allows us to better meet the needs of our clients, but compete head-to-head with low-cost sources in other countries.

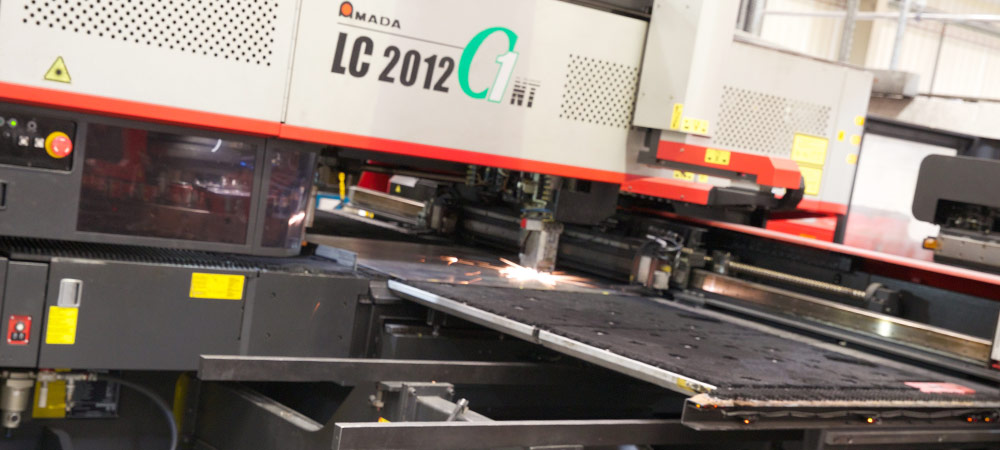

Our latest large-scale investment has been in a combination laser/punching machine from innovative, market-leading company, Amada. Their C1 is noted for both speed and accuracy, and at ASG it is fed by an Amada sheet load/unload unit capable of handling up to 3t of material. As this unit is fully automated, we are able to run the C1 on a 24-hour basis, without the need for operatives.

Suitable for both small batches and large runs, our laser tube cutting system can handle capacities up to a diameter of 152mm and a maximum length of 6500mm. With a subsequent reduction in wastage and the number of components required, it has meant significant cost savings for our clients, as well as a 70% improvement in productivity, achieved mainly by minimising sheet processes such as cutting, trimming, bending and welding. It has also removed the need for tooling in early-stage prototyping.

The main advantages of our Advanced Laser Cutting include:

- High-quality rigid joints

- Job changeovers in less than three minutes

- Faster programming from design to finished part

- Fully automated handling, including measuring, feeding, cutting and unloading

- Tube-specific CAD/CAM software control.